STANDARD

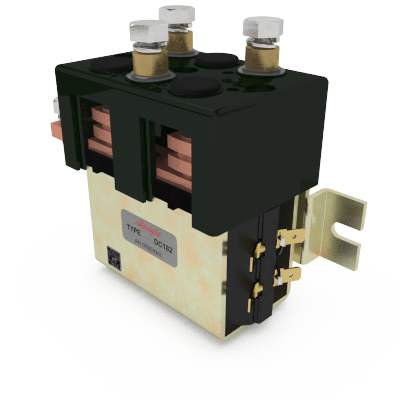

STANDARD DC182

MOTOR REVERSING

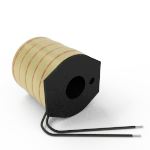

The DC182 contactor has been designed for direct current loads, particularly motors as used on electric vehicles such as industrial trucks and airport tractors.

The DC182 has double breaking main contacts with silver alloy contact tips, which are weld resistant, hard wearing and have excellent conductivity. The DC182 main contact circuit, designed for motor reversing, is such that it has a built in failsafe, so that if both coils are energised simultaneously the contact arrangement is open circuits. The DC182 is a monoblock construction, resulting in a neat compact design which is compatible with modern electronic control systems. Main terminals can be configured in a variety of ways in order to suit the application.

DC182 Technical Information

| Application | ||

| Thermal Current Rating | 150A | 150A |

| Intermittent Current Rating: | ||

| 30% Duty | 275A | 275A |

| 40% Duty | 235A | 235A |

| 50% Duty | 210A | 210A |

| 60% Duty | 195A | 195A |

| 70% Duty | 180A | 180A |

| Rated Fault Current Breaking Capacity (Icn) 5ms Time Constant: (In accordance with UL583*) | ||

| Blowouts | 1000A at 96V D.C. | |

| No Blowouts | 1000A at 48V D.C. | |

| Rated Fault Current Breaking Capacity (Icn) Resistive Load: (In accordance with UL508*) | ||

| Blowouts | - | |

| No Blowouts | - | |

| Maximum Recommended Contact Voltages | ||

| Blowouts | 96V | - |

| No Blowouts | 48V | - |

| Typical Voltage Drop per pole across New Contacts at 150A | 40mV | |

| Mechanical Durability | > 5,000,000 Cycles | |

| Coil Voltage Available (Us) (Rectifier board required for A.C.) | 6 - 240V | |

DC182 Features

| Component | Configurations |

|---|---|

| Auxiliary |

STANDARD STANDARD  STANDARD - GOLD STANDARD - GOLD  V3 V3  V3 - GOLD V3 - GOLD |

| Coil Suppression |

DIODE DIODE  DIODE AND RESISTOR DIODE AND RESISTOR  BI-DIRECTIONAL DIODE BI-DIRECTIONAL DIODE |

| Coil Terminations |

AMP TAGS AMP TAGS  FLYING LEADS FLYING LEADS  PLUG PLUG  VACCUM IMPREGNATION VACCUM IMPREGNATION |