London EV Show Review

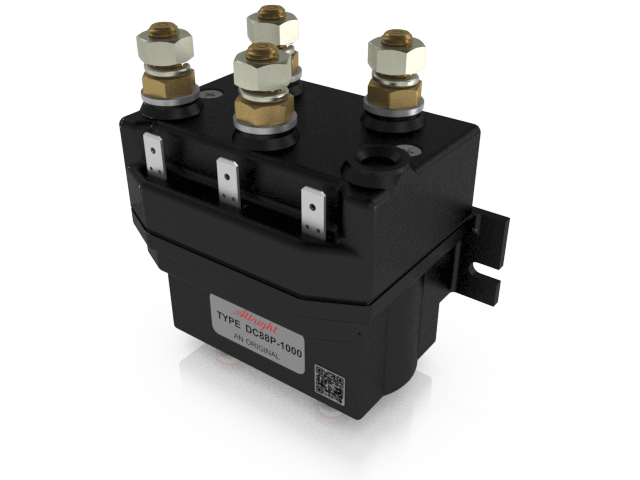

Last week, Albright International exhibited at the London EV show at the Excel London. Global Sales Director, Dean Crew, and European Technical Sales Manager Neil Makinson ventured to the British capital to discuss all things DC switching with several blue-chip clients. With conversations ranging from EV start up opportunities, golf buggies, Fire Engines and EV […]